Equipment For The Steel Construction Industry

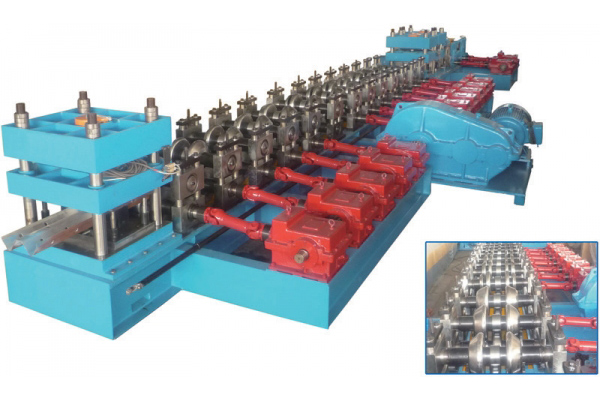

Our company’s professional manufacture high-quality Angle steel forming machine, KBK Rail Forming Machine, Guard Rail Forming Machine, Scaffold Plank Roll Forming Machine, Peach-Shaped Upright Forming Machine, CZ Interchangeable Steel Frame Purlin Roll Forming Machine

- Angle roll forming machine can produce 1.5-3mm angle steel.

- Peach-Shaped Upright Forming Machine.Strong decorative, beautiful and generous, solid anti – theft.Peach post guardrail shape is regular semi-ellipse, like peach shape, so called peach post.

Generally, the thickness of the plate of peach post is 1-1.2mm, which is formed by cold pressing and cold bending by machine.The outer side of the cylinder is elliptic, and the inner two plates, after being connected, bend outward respectively to make U shape, that is, the hook part.In order to facilitate the connection between peach post and the grid, N groups of hook notch are evenly distributed on both sides of the column according to the mesh size of the grid and the length of the column. The straight side of the u-shaped hook is tangent to the straight side of the elliptic column on the outside, which can effectively prevent from being pry open and ensure the anti-pry safety of the guardrail.

- CZ Purlin, trusses, horizontal roof beams perpendicular to the frame or rafters to support the rafters or roofing materials, purlins are transverse bending (usually bi-directional bending) members, usually designed as single-span simply supported purlins.

- Scaffold plank roll forming machine can make scaffold plank. We adopt servo feeder to make sure the holes are in high precision. We use punching press to make line speed faster and we use hydraulic post cutting to make sure the profile perfect.The thickness of raw material is around 1-2mm.

- Guardrail Roll Forming Machine can make W beam guardrail, thrie beam guardrail, also can be designed as two waves or three waves profiles in one machine just need to add some stations at the end of the machine.

- KBK Rail Forming Machine is mainly used in heavy industry, such as automotive, shipbuilding, assembly and machinery manufacturing and other fields need to be used, especially in warehouses, to lift materials for handling, this track can be used in places where operations are frequent, but also in short distances for lifting, equipment dense places can be lifted, so that this KBK track single girder suspension crane it is the use of linear track and other auxiliary components combined, generally at the two ends of the main beam where the trolley travels, and the main beam on the two hanging track for operation, single girder crane with hoist crane or wire rope crane is used in conjunction. And this rail single girder suspension crane has very good flexibility and freedom, can walk on the inclined track, but also to achieve variable track operation, the current span in ten meters, the lifting capacity is one tonmainly used in heavy industry, such as automotive, shipbuilding, assembly and machinery manufacturing and other fields need to be used, especially in warehouses, to lift materials for handling, this track can be used in places with frequent operations, but also in short distances for lifting, equipment dense places can be lifted, so that this track is very practical. KBK track Single girder suspension crane it is the use of linear track and other auxiliary components combined, generally at the two ends of the main beam where the trolley travels, with the main beam on the two hanging this track for operation, single girder crane with hoist crane or wire rope crane is used in conjunction. Single girder suspension cranes can be used in the transport of various flat objects, especially in production workshops, warehouses and other places can be used, and this track single girder suspension crane has very good flexibility and freedom to walk on the inclined track, but also to achieve variable track operation, the current span in ten meters, the lifting capacity is one ton.