– In all ladder systems in industrial facilities to ensure hygiene, ergonomics, slip resistance and durability.

– In the construction industry working areas for safety and stability play the role of non-slip scaffolding platforms and ladders.

– Portable camps on work platforms, stairs, sidewalks, driveways.

– In greasy, dirty, dusty and slippery work areas.

– In marine industrial facilities for waterproofing and slip resistance.

– All areas where portability, lightness and safety are required.

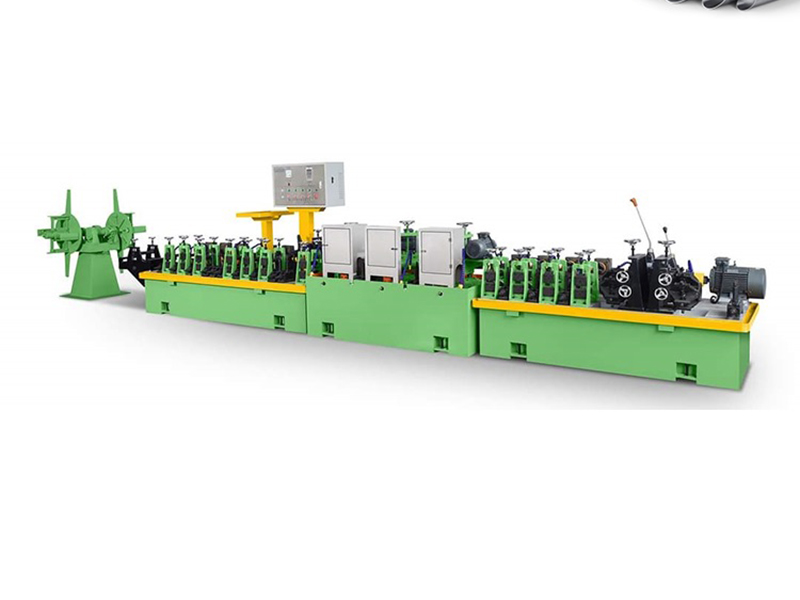

eScaffold plank Roll Forming Machine Process Flow:

Uncoiling and leveling machine—servo feeding—hydraulic punching —Forming mainframe —Unloading