Angle steel forming machine produced by the angle can be formed according to the different needs of the structure of different force members, but also can be used as the connection between the members. Widely used in various building structures and engineering structures, such as house beams, bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks, cable trench brackets, power piping, busbar bracket installation, and warehouse shelves, etc..

Angle steel is a carbon structural steel for construction, is a simple section of section steel, mainly used for metal components and plant framework, etc.. In use requires good weldability, plastic deformation properties and a certain mechanical strength. The raw material billet for the production of angle steel is low carbon square steel billet, and the finished angle steel is delivered in hot rolled, normalized or hot rolled condition.

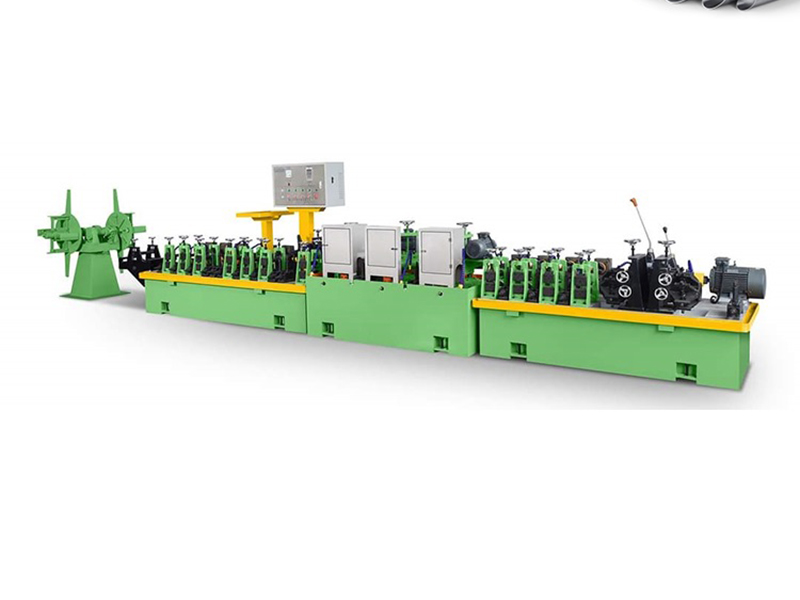

Angle Steel Roll Making Machine Process Flow:

Hydraulic uncoiling — Guided feeding — Clamping and feeding leveling — Roll forming —Cutting —Unloading