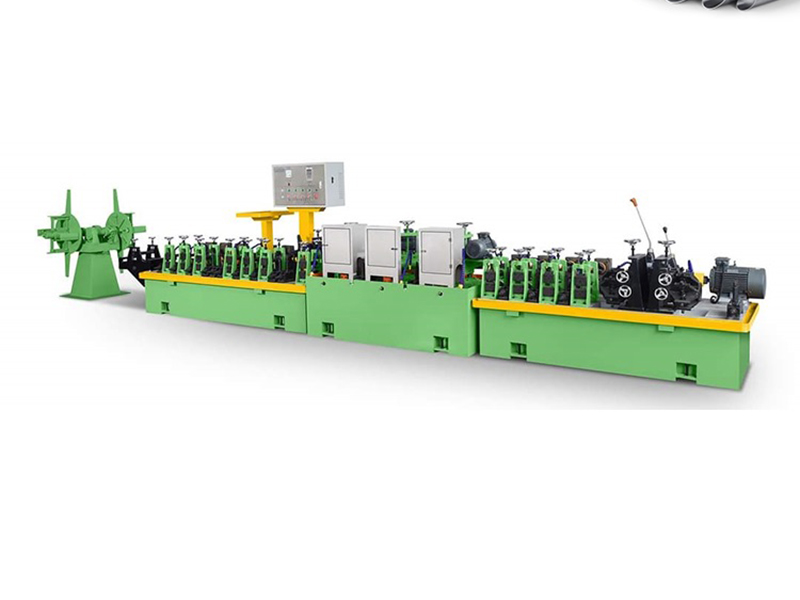

Main components of production line: uncoiler, forming and welding unit, grinding machine, sizing unit, straightening rack, cutting machine, finished product shelf

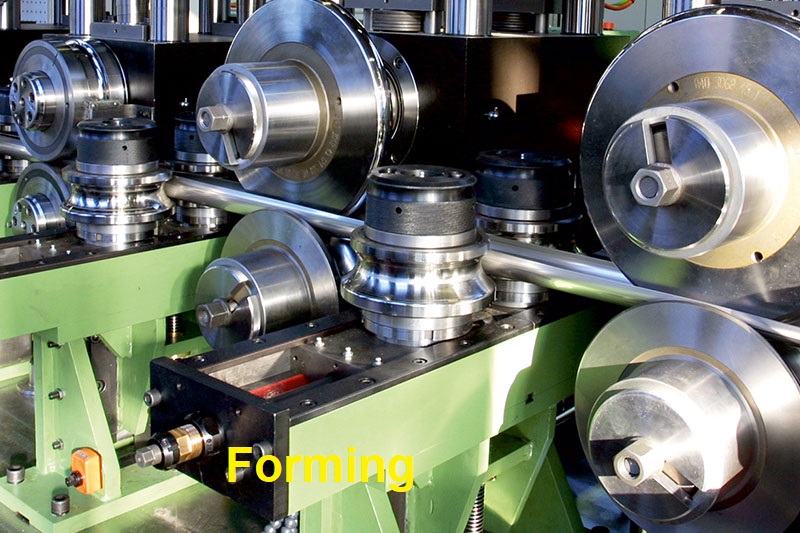

Production process: Uncoiler– Forming stage–Welding stage–Welded head grinding stage–Sizing stage–Automatic cut of stage–End- product frame

Production capacity:1-10 m/min

Welder type: Ultrasonic Welding machine

Cutting stage: Metal saw cutting stage

Application: Mainly used for decoration, products, appliances stainless steel pipe and carbon steel (round tube, square tube, shaped tube) production.

Specification

| Model | Horizontal

Shaft Size(mm)

|

Vertical

Shaft Size(mm)

|

Out

Diameter Range (mm) |

Thickness(mm) | Main motor

Power(kw) |

Dimension(meters) |

| 40S | 40 | 25 | 6-32 | 0.2-1.0 | 5.5 | 20 x 1.0 |

| 40 | 40 | 25 | 9-51 | 0.2-1.5 | 7.5 | 21.5×1.1 |

| 40L | 40 | 25 | 12-64 | 0.2-2.0 | 11 | 21.5×1.1 |

| 50 | 50 | 30 | 25-76 | 0.2-2.0 | 11 | 24×1.2 |

| 60 | 60 | 40 | 38-114 | 0.4-2.5 | 15 | 26×1.4 |

| 80 | 80 | 50 | 76-168 | 1.0-3.5 | 18.5 | 32×2.3 |

| 100 | 100 | 60 | 114-219 | 1.0-4.0 | 22 | 36×2.5 |