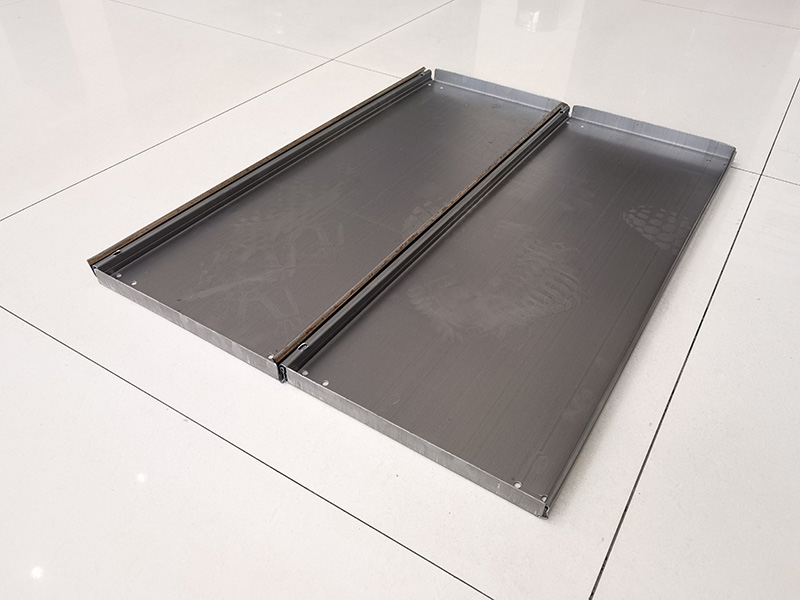

Shelving Panel Roll Forming Machine

is used to produce shelf components for warehousing series, and the finished product is “shelf panel”. It is mostly used for light shelf components such as goods display, placement, and merchandise display in warehouses, supermarkets, and small and large shopping centers.

Applications

1、The shelves can make full use of the warehouse space, improve the utilization rate of storage capacity and expand the storage capacity.

2、The goods stored on the shelves are not extruded and the material loss is small, which can completely ensure the function of the material itself and reduce the material loss.

3、The goods in the storage shelves are easy to access, easy to count and measure, and can be first in first out.

4、To ensure the quality of storage, moisture-proof, dust-proof, anti-theft, anti-loss measures can be taken to improve the quality of storage.

5、Many new shelves structure and function is conducive to the realization of mechanization and automation of warehouse management.

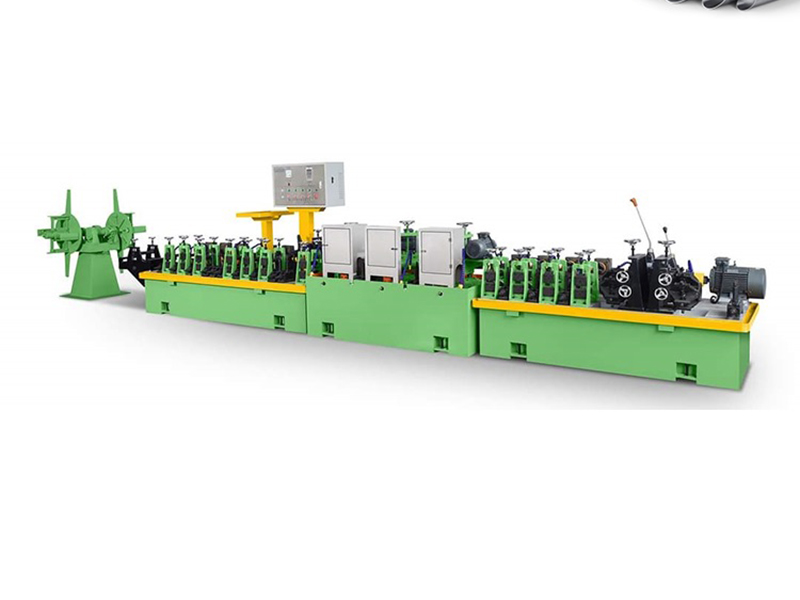

Process Flow:

Automatic uncoiler—guide—Pinching&leveling — roll forming — Straightening—Cutting —Unloading