Wave forming machine can produce corrugated metal tiles for industrial and civil buildings, warehouses, special buildings, large span steel roofing, house walls and exterior decoration, etc. It also includes some villages, supermarkets, hotels, exhibition halls, home buildings, shopping mall shutters and other buildings. Tile roll forming machine, roofing tile surface is very smooth and beautiful, the roof is not scratched.

Process Flow:

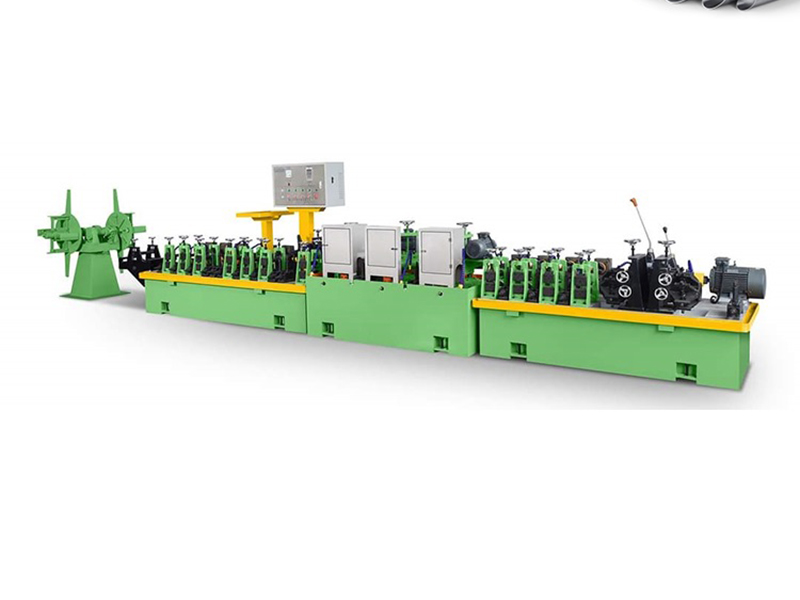

Passive uncoiler—Roll forming (including guided feed) — Cutting —Unloading